|

|

| |

| Hot-blast oven |

| |

Heated-Air Circulating Oven |

| |

Purpose:

Used in electronic parts, motor coils, electroplating parts, voltage transformer coils of electrical

machinery, chemical & pharmaceutical factories for plastic resin, dried/candied fruit, Screen Printing,

baking paint, vacuum metalizing, baking tea ,etc... Suitable for baking, preheating and tempering.

Available customized ovens are from 50℃ to 500℃

|

10ST-45 type

|

10ST-2 type

|

|

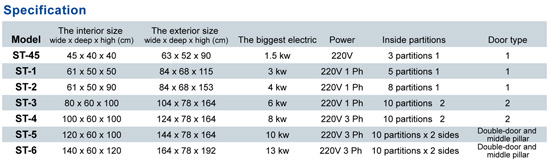

Standard specifications

1. All electronic temperature controllers, temperature is accurate.

2. Uses specialized motor of oven in the major axis type, reduced noise.

3. Hot-blast circulation via Horizontal Multi-blade Blower Wheel

4. Uses the electronic timer that has switch off automatic function.

5. The highest available temperature is 200℃.

6. Uses iron material (inside and outside), powder baking paint for conformation

(except ST-45 type).

7. Honeycomb heater has better cooling effect: (Usually, electric pipe heaters used in

countries outside Taiwan.

8. Appended trays which were made by nickel plating iron cloth.

(For other requests such as punched flats, flat-bottom trays or angled steel cloth trays

are considered separate)

※Devices may be added to prevent overheating, PLC. Inside material can be made

from stainless steel etc.

|

|

| |

10ST-3

|

This aircraft type oven preheats and bakes the item.

Time control function for micro-computer (semiconductor and LED) temperature.

The precision procedure saves valuable manpower and reduces electricity usage

|

Standard specification

| Interior size |

60W x 60D x 60H (cm) |

| Exterior size |

137Wx92Dx133H(cm) |

| Controller |

2 microcomputer temperature controllers show temperature and time 99H59M. |

| Hot-blast motor |

1/2HP (3 phases) |

| Electric |

6KW 220V/380V (3 phases) |

| Power Control |

4 - 20MA SCR non contact relay |

| Inside partitions |

10 doses plate nickel iron network in counting |

| Electric features |

voltmeter, ampere meter, indicator lamp,

start-up switch, etc. |

| Safety features |

1.Overheating prevention device has outage alarm

functions.

2.Overload protection. |

| Temperature |

Two kinds as 600℃ and 500℃ |

| Maximum temperature |

200 degrees Centigrade. |

|

| |

| Vacuum oven |

| |

This aircraft type is used in LED deaeration, epoxy resin ornaments industry, chemical industry , pharmaceutical, etc...

The advantages of this oven are the high vacuity, low fault rate, low maintenance cost and the window for viewing the products.

|

10STV-40

|

Standard specification

| Model |

STV-30 |

STV-40 |

STV-50 |

| Interior size(cm) |

30Wx30Dx30H |

40Wx45Dx40H |

50Wx50Dx50H |

| Heat controlling device |

Microcomputer temperature controller |

| Heater |

U style heating. Board heated from the outside |

| Relay |

Relay SSR solid state relay |

| Vacuum pressure gauge |

0 -76 vacuum pressure gauges |

| Window |

Double layered tempered glass |

| Vacuum valve |

A " ball type valve " |

| Broken vacuum valve |

1/2 " ball type valves " |

| Vacuum washer |

Silicon rubber shaping |

| Electric |

220V single-phase 50/60HZ |

| Temperature |

Available to 200℃ |

| Electric current |

1.2KW |

2KW |

3KW |

|

Use in normal atmospheric conditions - 200℃

Can design according to your needs

1.Variable temperature control.

2.The atmospheric temperature can reach up to 400℃. |

| |

|

|